Macadamia Nutcrackers & Hoppers for Fast, Reliable Processing

Macadamia Nutcracker

Since the beginning of the Macadamia industry in the Northern Rivers, McKEECO General Engineering has been building and servicing the MKI nutcracker. Since then, we have seen them installed in major farming and food processing facilities across Australia & Overseas.

Late 2016 saw a significant re-design and the birth of the MKII cracker, a smaller, simpler machine with the same capacity as the MKI. All components are manufactured using state-of-the-art CNC machines with the latest in tooling.

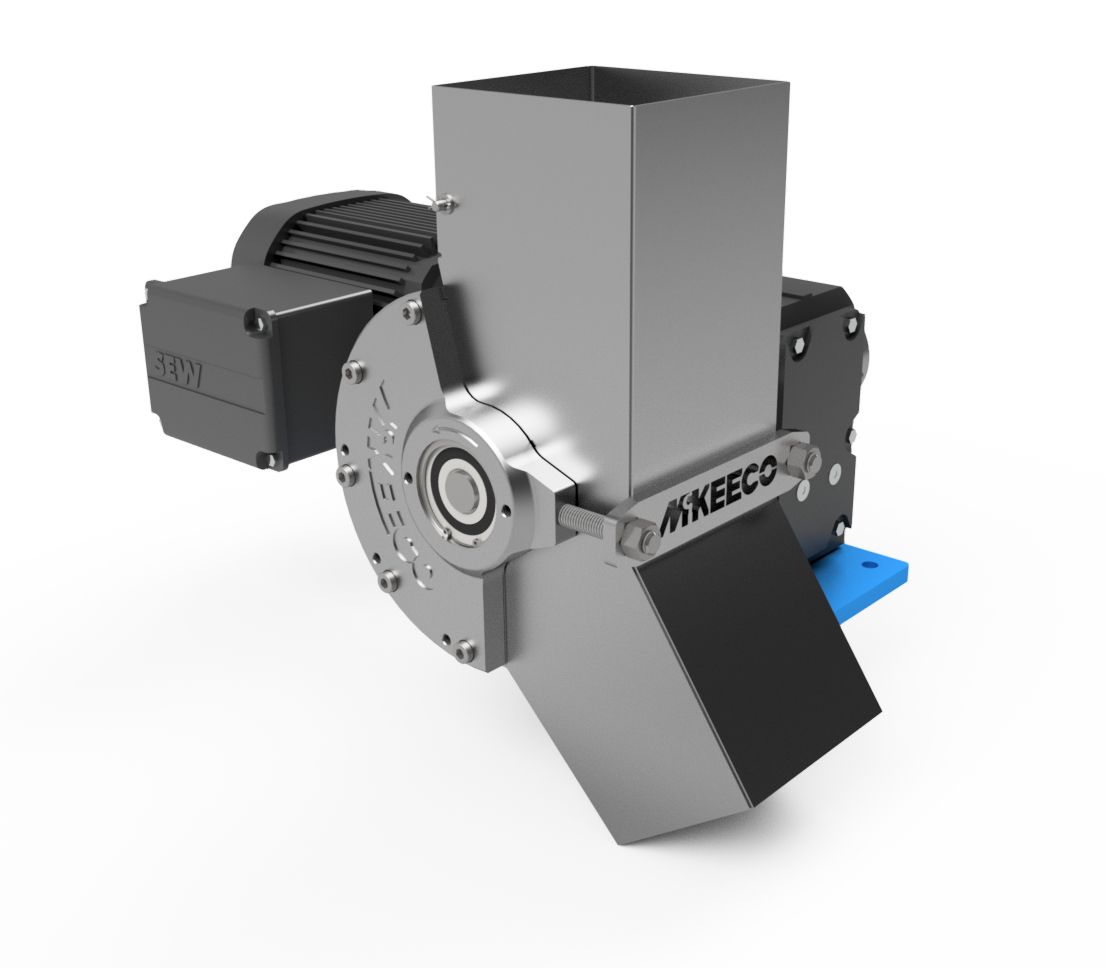

MKII Nutcracker

McKEECO MKII Nutcracker is a Single Chamber Direct Drive commercial unit designed to crack up to 450kg/hr of ungraded nut in shell, using a rotary cracking action against blades. The cracking rotor is driven by a motor gearbox combination mounted directly onto the rotor shaft. The cracking chamber is also mounted directly to the face of the heavy-duty gearbox.

Specifications

- Motor 0.75kW 1 Phase or 3 Phase

- Dimension 0.4m x 0.37m x 0.53m

- Weight 66 kg

- Components:

- Cracking chamber fitted with nutcracker blades

- Stainless steel delivery chute

- Drive: Motor and heavy-duty gearbox

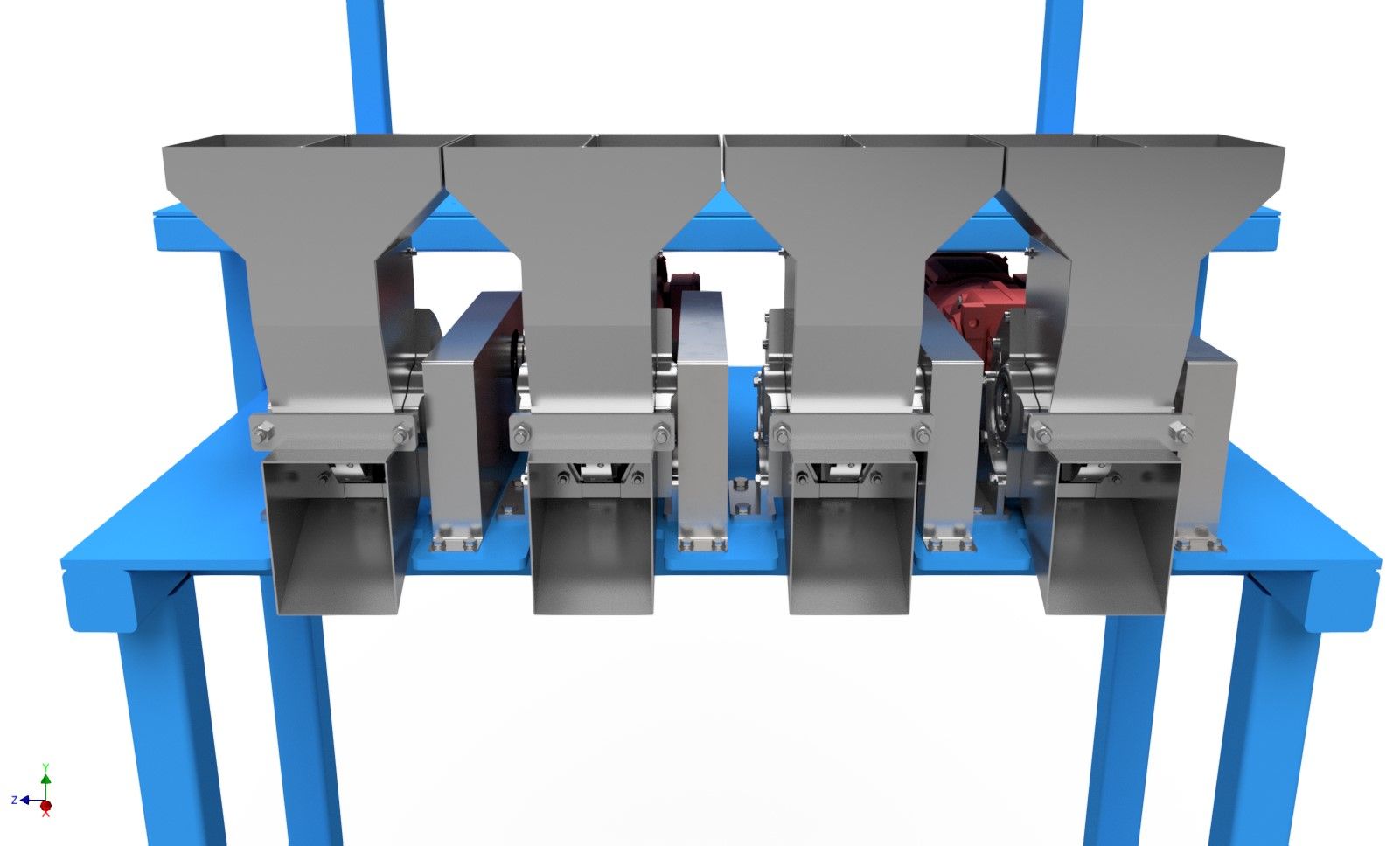

We can custom-make the MKII into doubles or quads for large scale operations.

Vibrating Infeed Hopper

We can provide a semi-automated vibrating infeed hopper to suit our MKII nutcracker as an optional extra.

Features:

- 33Litre, 316 Stainless steel storage hopper (made in Aus.).

- Electromagnetic vibration unit (made in Germany).

- Maintenance-free operation.

- Easily adapted onto the standard MKII cracker.

- Simplifies the cracking process.

- Adjustable vibration speed controller.

- Up to 450kg/h cracking capabilities.

Improve your efficiency with our macadamia nutcracker and hopper. Contact us to get started.